Case studies

Mirror polishing for molds sample

Partial introduction.

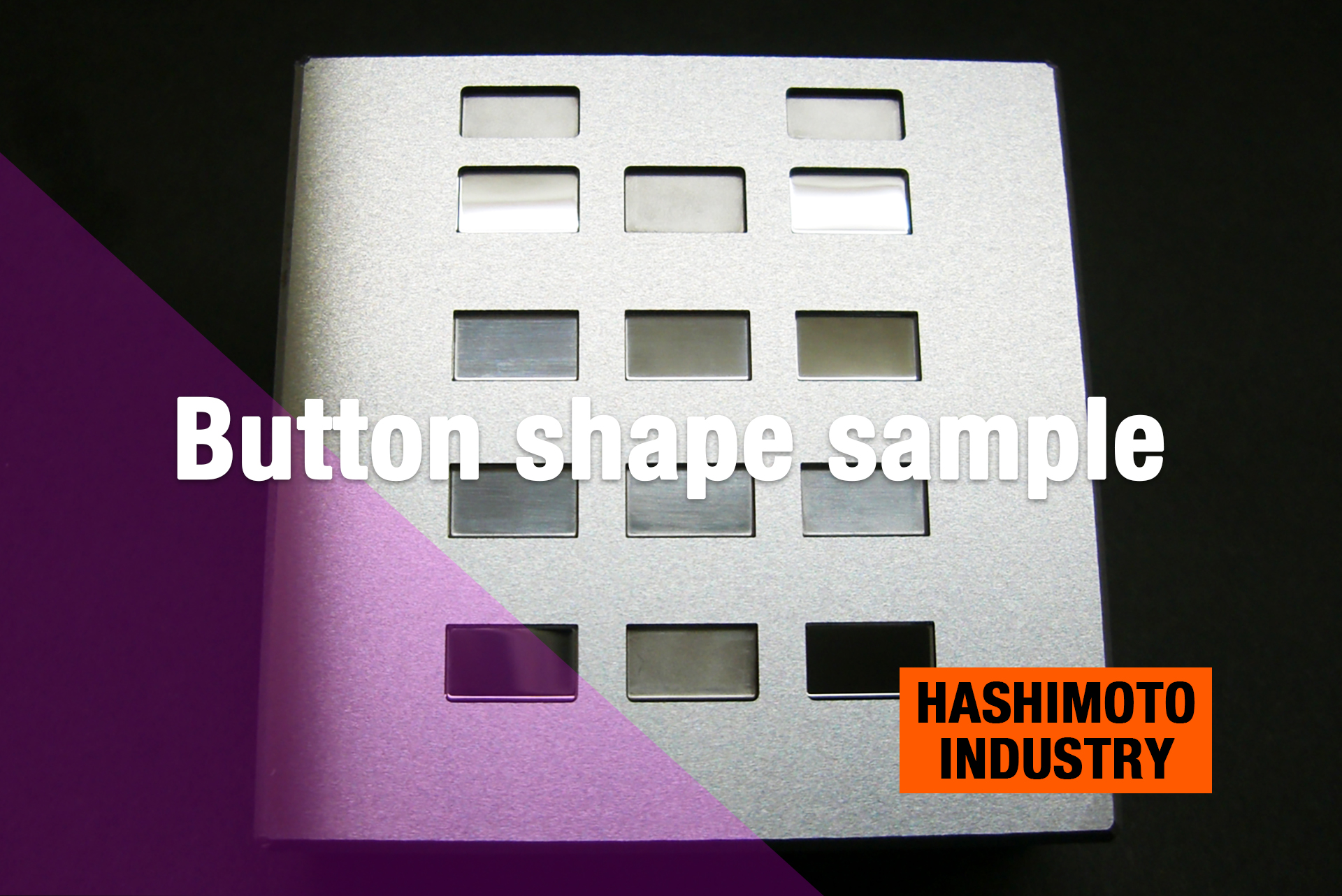

Sample of button configuration.

The mobile phone button shapes have undergone electric discharge processing. Once these processing lines have been completely removed, the list of further processes includes application of the grindstone, paper treatment, shine production and the mirror completion processes. Even with a small area, unless the surface is completely flat it cannot be described as a “mirror surface”. Hashimoto Industry excels at this kind of precision work.

Sample of reflector configuration.

Polishing repeatedly until the processing lines are removed without destroying the shape and carrying out the finishing processes for the perfect shine by hand for each and every process requires unrivaled concentration and determination. Moreover, because the sample is considerably heavy it is not possible to change the direction to make the work easier. The finished mold reflects light like a jewel. (Post-polishing on the left and pre-polishing on the right.)

Sample of audio panel polishing.

This kind of mold, with several angular and protruding buttons, faces a certain problem at the grindstone stage. The problem is that grooves arise in certain locations, similar to the “crossings” of a road. When trying to finish a mirror, it is unacceptable to have even the slightest distortion in the surface. Grindstone work, which ultimately decides the final dimensions of the mold, is an unimaginably delicate process.

Sample of keyboard mold polishing.

Molds for keyboards need to be of the “superfine” quality ranking because top musicians will notice during performances when there are distortions, even if these are at a level that is impossible to detect by the naked eye. Identifying these tiny distortions is so tough that there are very few testing technicians capable of making these judgments. Even in Japan, there are very few companies capable of producing “superfine” quality. One of these is Hashimoto Industry.